The Strategic Value of Skill Management for Technical Teams

Building High-Performance Teams

As a manufacturing HR leader or operations manager, youre likely facing a perfect storm: experienced machinists retiring, technology evolving faster than ever, and pressure to maintain quality while increasing output. The solution? It might be simpler than you think – but it requires rethinking how we manage and develop talent in precision manufacturing.

The Changing Face of Manufacturing Talent

Gone are the days when a machinist learned one machine and operated it for their entire career. Todays manufacturing environment demands adaptability. Your veteran machinists carry decades of invaluable experience, while your newer team members bring digital fluency thats essential for modern operations. This generational diversity creates powerful advantages – younger workers consistently prioritize skill development and growth opportunities in their career decisions, making them ideal candidates for todays evolving manufacturing environment.

The Real Cost of Neglecting Skill Management

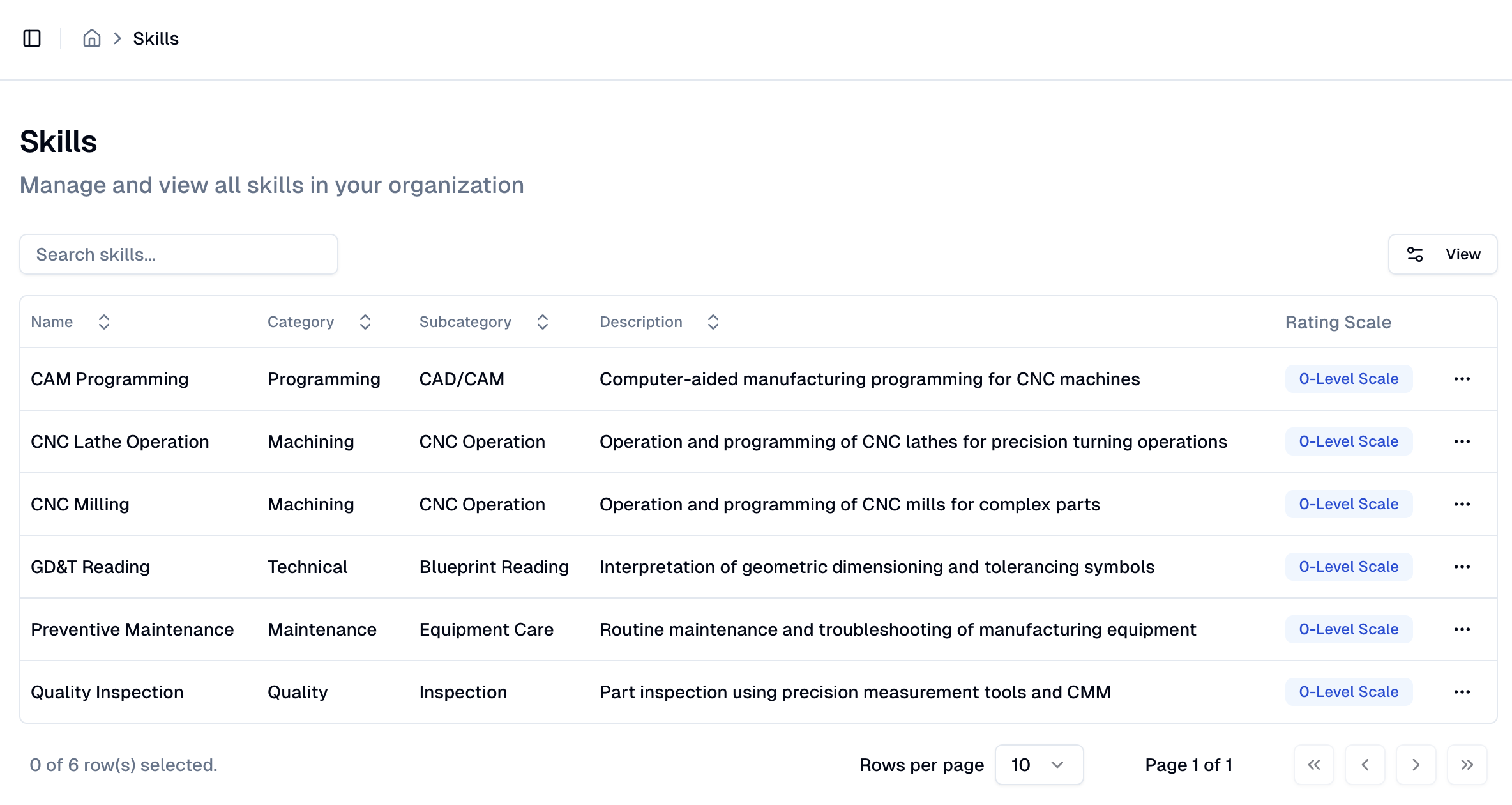

Lets be honest – many shops still track skills on spreadsheets or, worse, rely on tribal knowledge. This approach might have worked a decade ago, but today it creates serious business risks:

Immediate Production Impact

The daily consequences of inadequate skill management ripple throughout production operations. When key operators are absent, quality often becomes inconsistent as less experienced staff struggle to maintain standards. Setup times lengthen as cross-training opportunities are missed, while limited operator flexibility reduces the shops capacity to take on new work. Perhaps most costly is the elevated scrap rate that comes from inadequate training documentation and knowledge transfer.

Strategic Business Risks

Think beyond the day-to-day production challenges to the longer-term strategic implications. Poor skill management creates an overreliance on irreplaceable tribal knowledge, leaving shops vulnerable to sudden departures. Without documented competencies, shops often cant bid on lucrative contracts in regulated industries. Innovation stalls as new technology adoption becomes impossible without proper training infrastructure, and recruitment costs soar due to limited internal advancement paths.

Building a Future-Ready Workforce

Forward-thinking machine shops are transforming how they approach skill development. Heres what theyre doing right:

Creating Clear Development Paths

Modern machinists want to understand their growth opportunities, and successful shops are responding with comprehensive development strategies. By mapping clear progression paths from basic to advanced operations, they create visible career trajectories that motivate and retain talent. These shops document specific competencies needed for each role, implement structured cross-training programs, and establish recognition systems that reward skill advancement. This systematic approach not only improves retention but creates a more flexible, capable workforce.

Embracing Technology Changes

As manufacturing technology evolves, leading shops are taking a proactive approach to skill development. Theyre integrating automation skills into their core training programs while developing hybrid roles that combine traditional machining expertise with modern programming capabilities. These organizations foster partnerships between experienced machinists and newer operators, creating an environment where digital competencies grow alongside traditional skills. This balanced approach ensures shops can leverage new technologies while preserving crucial institutional knowledge.

The Regulatory Reality

If youre supplying regulated industries (and most shops are), proper skill management isnt optional. Heres what you need to know:

Industry Requirements

- Aerospace requirements include detailed operator qualification records

- Medical device manufacturing demands documented training effectiveness

- Automotive standards require specific process competency verification

- Defense contracts often need security clearance alongside technical skills

Documentation Essentials

- Clear definition of required competencies

- Documented training procedures

- Regular skill assessments

- Training effectiveness verification

- Maintenance of qualification records

Future-Proofing Your Operation

The shops that will thrive in the next decade are making strategic decisions today about their workforce development. Consider:

Technology Integration

- How will automation complement (not replace) your skilled workforce?

- What new skills will your team need as technology evolves?

- How can you create effective human-machine partnerships?

Workforce Development

- What training methods work best for different generations?

- How can you capture critical knowledge before retirements?

- What career paths will attract and retain top talent?

Conclusion

Effective skill management isnt just about compliance or efficiency – its about building a sustainable competitive advantage. In todays manufacturing environment, your ability to develop and maintain critical skills directly impacts your bottom line and future growth potential.

Share this article

Related Posts

Learn how skill matrices help organizations track and develop employee capabilities effectively across any industry.

A comprehensive guide to implementing and maintaining successful skills management programs in any organization.